Corrugated Polycarbonate Sheet Manufacturer

As the name suggests, the corrugated polycarbonate roof tile has a regular corrugated shape. This corrugated structure is by no means a decorative design, but the result of scientific considerations. The existence of the corrugation not only enhances the longitudinal strength of the board, so that it can disperse the pressure when subjected to external forces and improve the overall anti-deformation ability, but also effectively guides rainwater and snow to slide quickly, avoiding water and snow accumulation from causing excessive load on the roof.

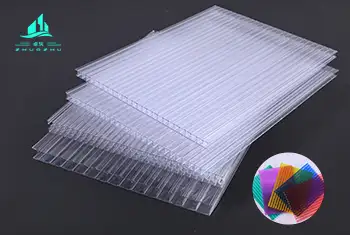

Corrugated Polycarbonate Sheet

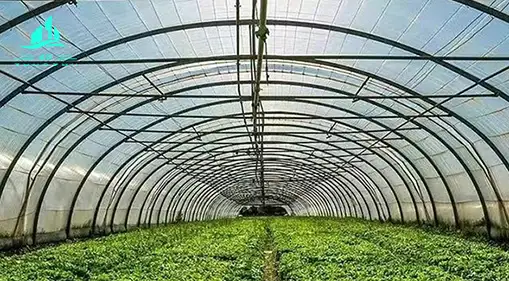

With a light transmittance of up to 85% – 90%, corrugated polycarbonate roof tiles can not only ensure good lighting effects, but also make the light softer, reduce glare, and create a comfortable light environment for the room. In addition, polycarbonate has a stable molecular structure and excellent weather resistance. Whether it is severe cold or heat, or long-term exposure to ultraviolet radiation, it is not prone to aging, deformation, fading and other problems, and the service life can reach 15-20 years or even longer. To further improve performance, ZHUOZHU corrugated polycarbonate roof tiles will also add an anti-ultraviolet (UV) coating on the surface, which can effectively block more than 99% of ultraviolet rays, not only protecting the board itself, but also preventing ultraviolet rays from entering the room, protecting indoor furniture and decorative materials from ultraviolet damage.

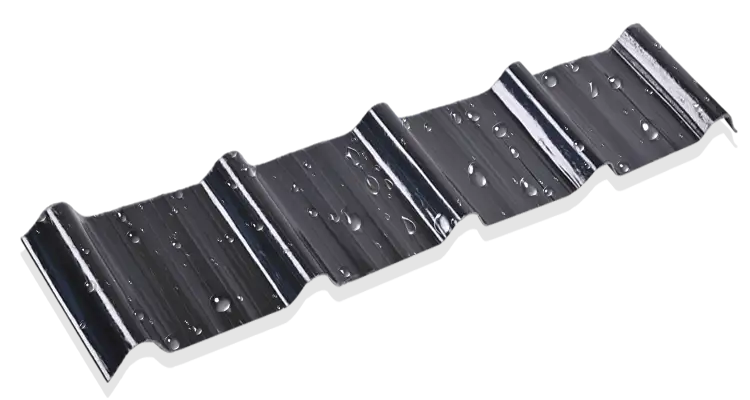

No Water Stains

When rain falls on the tiles, it quickly gathers into water droplets and rolls down, making it difficult to form water stains. Even if there are occasional small water marks, they can evaporate quickly under the sunlight without leaving any traces, keeping the roof clean and transparent at all times, making the building look new for a long time. At the same time, this feature of not leaving water stains can also prevent impurities in the water from adhering to and breeding algae or moss, reducing the frequency and difficulty of later cleaning and maintenance.

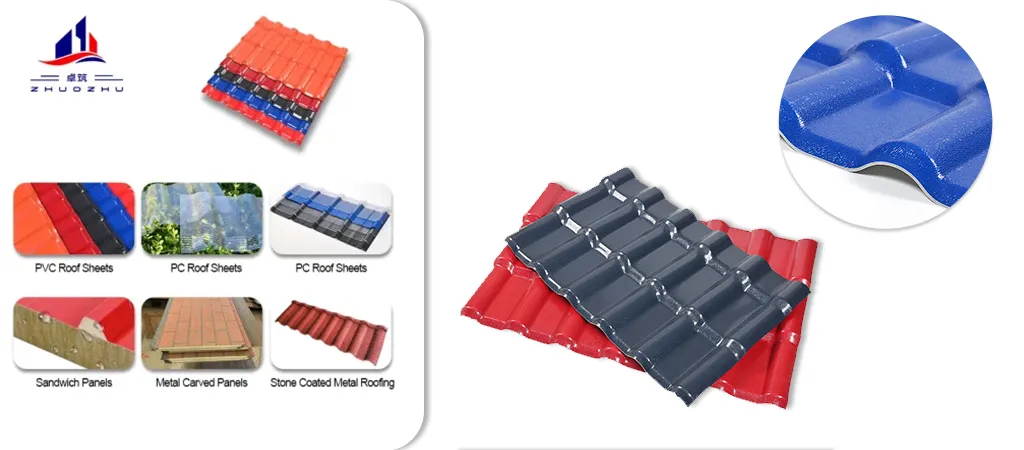

Production Workshop and Product Display

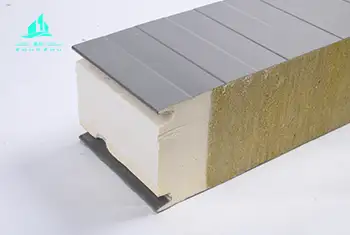

We have large-scale automated production equipment that can meet the simultaneous production of various products, regardless of the size of your order. In addition to producing pure polyurethane panels, rock wool sandwich panels, insulation sandwich panels, roofing sandwich panels, cold room panels and other products, ZHUOZHU can also quickly produce any sandwich panel products that meet the needs of your project.

OEM&ODM

Product customization > Payment of deposit > Sample confirmation > Final payment > Production and shipment > Receipt and inspection

General Faq

Design your beautiful Elementor FAQ widget and get more traffic to your website.

How to ensure quality?

Delivery time?

What is the payment method?

What are the benefits of buying products from ZHUOZHU?

What is the service life of sandwich panels?

ZHUOZHU BLOG

Learn about manufacturing processes, technologies and materials

A Study on the Performance of Plastic Roofing Tiles Under Different Climatic Conditions

This study systematically analyzes the durability, thermal performance, and long-term service behavior of lightweight plastic roofing tiles under various climatic […]

Timber Frame Houses with Metal Carved Panels: The Perfect Balance of Innovative Combination

In modern architectural practice, the combination of timber frame houses and metal carved panels is gradually becoming a building solution that […]

Rock Wool Sandwich Panels: Unparalleled Fire Performance and Comprehensive Advantages

In the evolution of building materials, fire safety has always been the primary consideration. Rock wool sandwich panels stand out […]