China Metal Carved Board Supplier

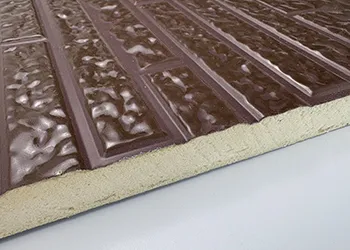

Practical and beautiful at the same time, the unique aluminum foil protective layer plays a role in heat insulation and moisture resistance, which can effectively reflect heat sources, prevent heat loss, and avoid external moisture intrusion.

Metal Carved Board

Insulation, heat insulation, beautiful and fireproof.

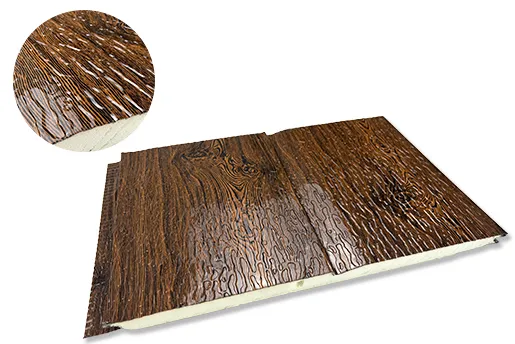

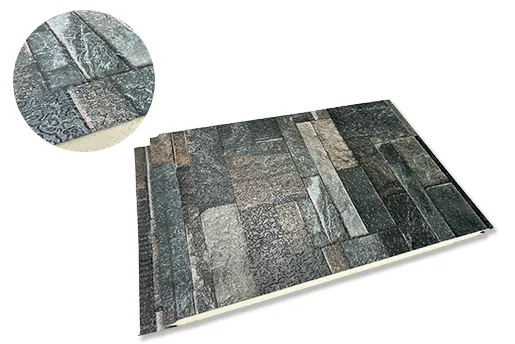

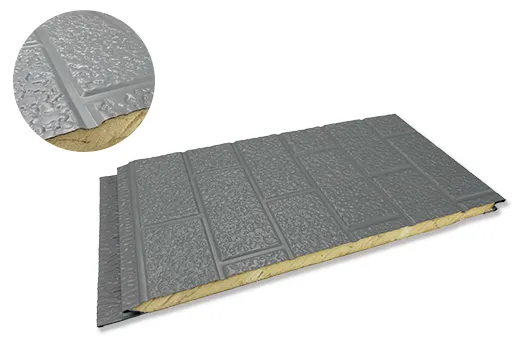

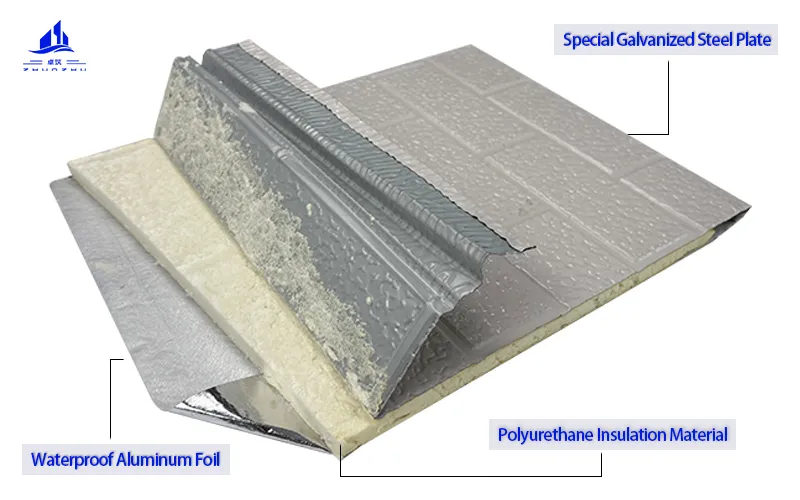

The basic structure of the metal carved boards is that the surface is a high-quality color embossed metal plate (such as aluminum-zinc-coated steel plate, stainless steel, etc.) treated with a special layer. Various patterns are formed through carving, stamping and other processes and fluorocarbon coating is performed. The core material is a hard high-density polyurethane foam and other thermal insulation materials that have been treated with flame retardant. The interior is an independent closed bubble structure, and the inside is an aluminum foil protective layer that plays a role in heat insulation, heat preservation and moisture-proof.

Practicality and beauty coexist - Carved Metal Boards

Carved metal insulation boards have thermal insulation properties, which can reduce heating and cooling energy consumption; they are easy to install, and the prefabricated installation is not restricted by seasons or geography, which can shorten the construction period; they are lightweight and earthquake-resistant, which reduces the burden on buildings and is earthquake-resistant and crack-resistant; they are waterproof and moisture-proof, and their excellent structure can prevent water seepage on the walls and mold indoors; they are soundproof and noise-reducing, and the independent closed bubble structure of the core material can block outdoor noise; they are green and environmentally friendly, with stable chemical and physical structures, and can be recycled and reused; they are highly decorative, with more than a hundred kinds of pattern and color combinations, which can achieve the effect of high-end decorative materials.

Production Workshop and Product Display

Metal carved wall panels have a wide range of applications. They can be used for the decoration and energy-saving renovation of new houses (such as brick-concrete, frame, steel structure, etc.) and existing houses, such as villas and apartments. They are also suitable for the exterior wall insulation decoration of public buildings such as office halls, schools, and hospitals. They can also play a role in municipal construction projects such as guard booths and mobile public toilets, and can also be used for the decoration of pavilions, rest corridors and other buildings in garden attractions.

Ready to Get a Quote?

Take advantage of our network and see what Ecox can do for you.

Thermal insulation, waterproof and flame retardant

The carved metal insulation wall boards themselves have the characteristics of thermal insulation, waterproof and flame retardant, lightweight and earthquake-resistant, easy construction, sound insulation and noise reduction, green and environmental protection, beautiful and durable. Because of its simple and practical assembly method and not restricted by seasonal environment, it is very safe and convenient to install and use, suitable for all seasons.

Super strong thermal insulation

Polyurethane foam is currently the most advanced and environmentally friendly thermal insulation material in the world. With the backing aluminum foil, the thermal insulation effect is optimal. The unique structure effectively prevents heat loss in winter and reduces the heat of the summer sun.

Carved Metal Insulation Panels: The Perfect Fusion of Traditional and Contemporary Architectural Aesthetics

The design of the ZHUOZHU metal carved panel achieves a thermal conductivity of 0.022W/(m·K) with only 60% of the thickness of traditional sandwich panels, maximizing material efficiency.

The Ingenious Balance of Material Structure

Carved metal insulation panels adopt a three-layer composite structure:

- Surface layer: 0.5-0.8mm thick pre-coated metal sheet with CNC-punched three-dimensional patterns.

- Core layer: High-density polyurethane foam (density ≥45kg/m³).

- Backing layer: Aluminum foil composite reinforcement membrane.

Intelligent Compromise in Thermal Performance

Notably, the “strategic concession” in insulation performance demonstrates wisdom in building physics:

20-30% thickness reduction enables greater design flexibility and lighter structural loads.

Suitable for most commercial buildings in temperate climates (U-value controlled at about 0.35W/(m²·K)).

Compensates insulation through air cavity design, creating an integrated “insulation-decoration-ventilation” system.

Digital Evolution of Pattern Libraries

Modern carved metal panel patterns have entered the parametric era:

BIM-integrated pattern libraries support real-time visualization.

Customization level exceeds 90%, with minimum repeat units controllable at 300mm.

Dynamic light-shadow effects created through varying stamping depths (0.5-3mm).

Breakthroughs in Material Simulation

Latest technologies enable:

Brick patterns: 1:1 reproduction of masonry textures including mortar joints.

Wood grains: Micron-level surface treatment simulating real wood texture.

Stone textures: Nano-coating technology recreating natural stone color variations.

Production Innovations

- Water-based UV-cured coatings reduce VOC emissions by 85%.

- CNC punching achieves 98% material utilization rate.

- Closed-cell foaming technology reduces polyurethane material consumption by 15%.

Usage Advantages

- Reflective surface treatment reduces heat gain, lowering AC energy consumption.

- Modular design enables single-panel replacement.

- Expected service life exceeds 25 years with 3x extended maintenance cycles.

Digital Evolution of Pattern Libraries

- 100% recyclable metal surface.

- Overall material recyclability reaches 92%.

Mature pyrolysis technology for polyurethane core.

Innovative Applications

- Commercial complexes: Defining functional zones through pattern variations.

- Urban renewal: Facade revitalization without structural modifications.

Cultural architecture: Telling regional stories through custom patterns.