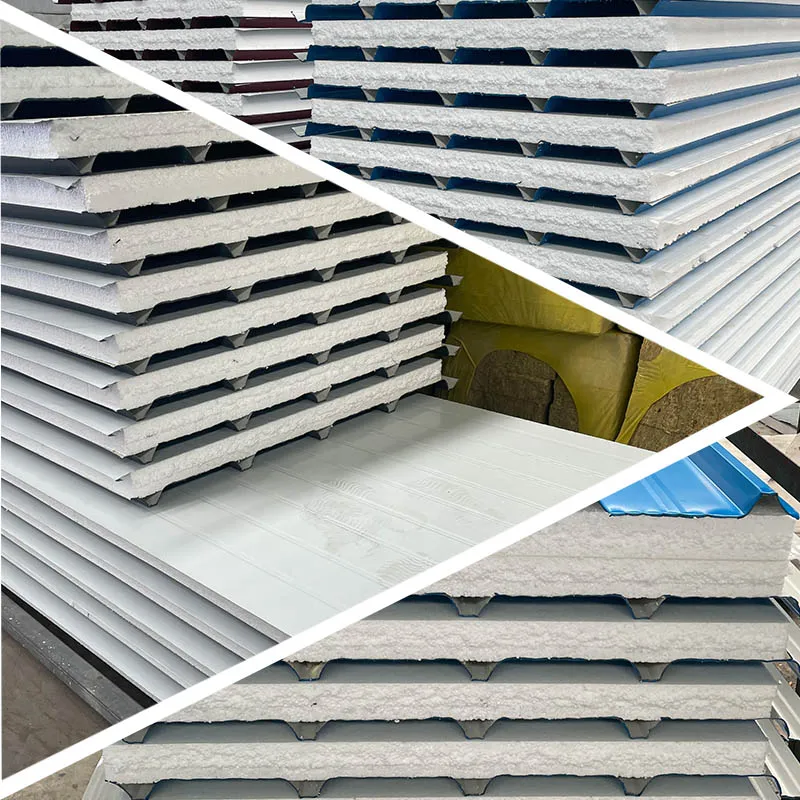

EPS Sandwich Panel

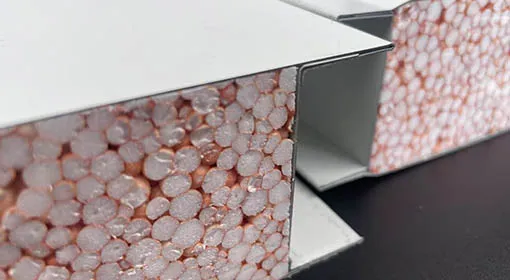

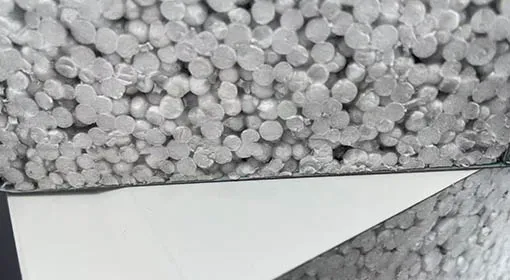

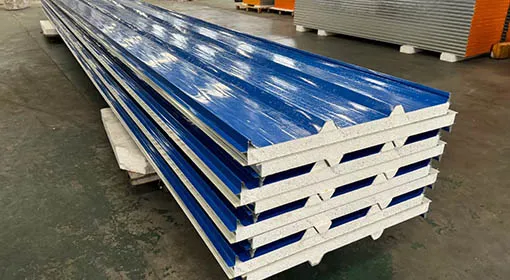

EPS sandwich panels are composite foam sandwich panels made with an Expanded Polystyrene (EPS) core sandwiched between two rigid facings, typically steel, aluminum, or fiber cement. These panels are widely used in construction for walls, roofs, and partitions due to their lightweight, thermal insulation, and structural strength.

✔ Excellent Insulation – EPS core provides superior thermal and acoustic insulation.

✔ Lightweight & Easy to Install – Reduces structural load and speeds up construction.

✔ Durable & Weather-Resistant – Ideal for EPS sandwich panel houses and industrial buildings.

✔ Cost-Effective – Lower transportation and labor costs compared to traditional materials.

EPS sandwich panels come in various thicknesses, with 50mm EPS panels and 75mm EPS sandwich panels being the most popular:

50mm EPS Panel: Best for interior partitions and moderate climates.

75mm EPS Sandwich Panel: Offers higher insulation, suitable for extreme temperatures.

Description

EPS sandwich panels are high-performance composite foam panels featuring an EPS core (12-30 kg/m³ density) sandwiched between steel, aluminum, or fiber cement facings. Available in 50mm and 75mm thicknesses, these panels deliver exceptional thermal insulation (R-value 1.25-1.9 m²K/W), soundproofing (25-35 dB), and fire resistance (Class B1). Compared to traditional materials, they offer 60% faster installation, 40% cost savings, and 30% better energy efficiency – making them ideal for residential homes, warehouses, and prefab structures.

As a leading EPS sandwich panel factory, we provide certified panels (ISO 9001, CE) in custom sizes (up to 12m length) with load-bearing (150 kPa) and fire-resistant (Class A2) options. Case studies show 2,000m² warehouses built 50% faster with 30% energy savings using our 75mm EPS panels. Whether you need lightweight 50mm EPS panels for cost efficiency or 75mm EPS sandwich panels for maximum insulation, our solutions combine proven performance data with factory-direct pricing. Contact us for a project-specific quote today!

Tell us your special requirements for sandwich panels

If our standard styles don’t quite meet your needs, we also offer custom made services.

Superior Properties of EPS Sandwich Panels

As an efficient, economical, and versatile building material, EPS sandwich panels are playing an increasingly important role in modern construction. Whether in 50mm or 75mm sizes, these composite foam sandwich panels offer reliable thermal insulation solutions for a wide range of building projects. With increasing energy-efficiency requirements and technological advancements in building construction, EPS composite panels will continue to innovate and develop, providing the construction industry with even more high-quality product options.

Excellent Thermal Insulation

EPS sandwich panels are renowned for their exceptional thermal insulation properties. The EPS foam core has an extremely low thermal conductivity, effectively preventing heat transfer and significantly reducing building energy consumption.

Strength-to-Weight Ratio

The unique design of EPS sandwich panels gives them a high strength-to-weight ratio, enabling them to withstand substantial loads while reducing the overall structural burden and simplifying installation.

Fire Safety

Modern EPS sandwich panels undergo special fireproofing treatments, resulting in excellent flame retardancy. High-quality EPS sandwich wall panels typically meet B1 flame retardant standards, effectively enhancing building safety.

Environmental Protection

EPS material itself contains no harmful substances and is recyclable, aligning with green building principles. Using EPS composite foam sandwich panels can help reduce energy consumption throughout a building’s lifecycle, thus reducing its carbon footprint.

General Faq

Design your beautiful Elementor FAQ widget and get more traffic to your website.

How to ensure quality?

Delivery time?

What is the payment method?

What are the benefits of buying products from ZHUOZHU?

What is the service life of sandwich panels?

ZHUOZHU BLOG

Learn about manufacturing processes, technologies and materials

Steel Structure and Sandwich Panel

1. What is a Steel Structure? A steel structure is a load-bearing structural system made of steel materials (typically structural sections, steel plates, steel […]

Twin Wall Polycarbonate Greenhouse Panels: The Ultimate Guide

If you’re a gardening enthusiast looking to build or upgrade a greenhouse, you’ve likely encountered twin wall polycarbonate greenhouse panels. But […]

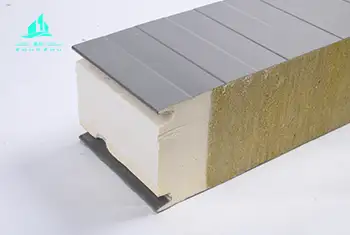

Rock Mineral Wool Sandwich Panels: Building a Safe, Energy-Efficient, and High-Performance Building Envelope System

Rock Mineral wool sandwich panels are high-performance building materials that integrate fire resistance, thermal insulation, sound absorption, and load-bearing capabilities. […]