PU Polyurethane Sandwich Panel

China PU Polyurethane Sandwich Panel Supplier/Manufacturer

Home > Sandwich Panels > PU Sandwich Panel

PU Polyurethane Sandwich Panel

- Steel plate thickness: 0.2 – 0.8mm

- Sandwich thickness: 50mm, 75mm, 100mm, 150mm, 200mm

- Width: 950mm, 980mm, customized

- Fire rating: B

- Service life: 5 – 20 years

Description

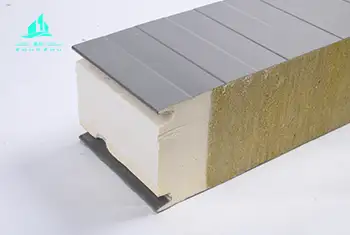

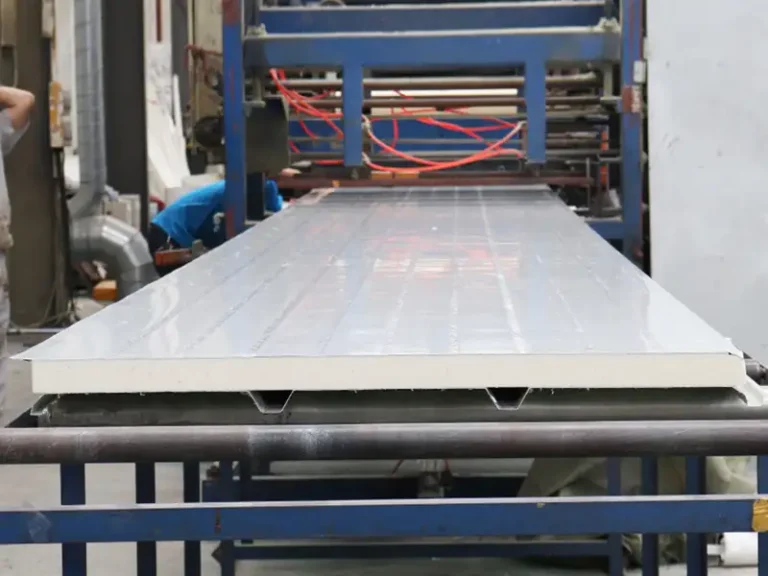

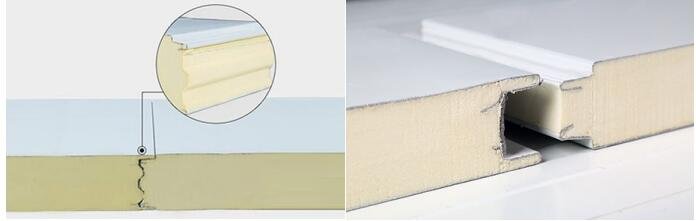

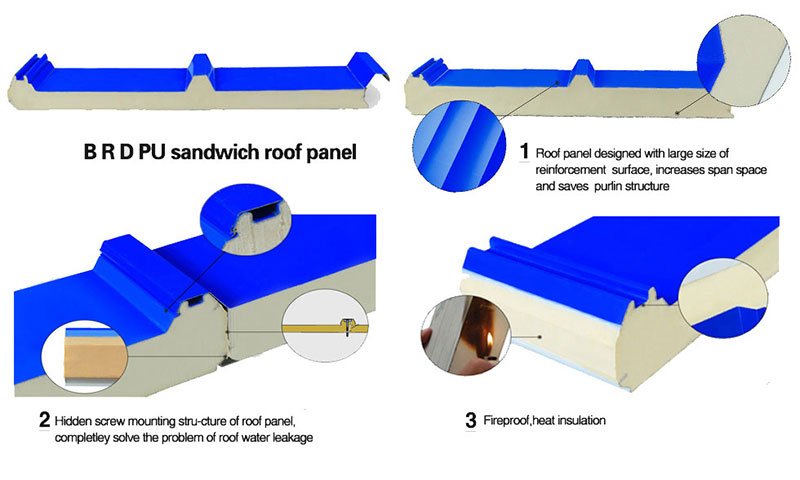

As an innovative material in the construction field, polyurethane sandwich panels have become an ideal choice for many construction projects with their excellent performance. It is composed of an outer metal panel and a middle polyurethane core material. The outer metal panel, such as color-coated steel plate, stainless steel plate or aluminum alloy plate, not only gives the plate a beautiful appearance, but also meets the weather resistance, antistatic, anti-corrosion and antibacterial requirements in different environments through special surface treatment. The middle polyurethane core material is formed by the foaming reaction of isocyanate and polyol, and has a closed-cell honeycomb structure. The density is usually 30-40kg/m³, with stable chemical properties and strong anti-aging ability.

Product Features

In terms of performance, polyurethane sandwich panels have many highlights. Its fire resistance level is excellent. The ordinary type can reach B1 level (flame-retardant level) specified in GB8624. It is not easy to spread fire and has low smoke density when burning. After adding high-efficiency flame retardants, it can be close to Class A standards, suitable for places with strict fire protection requirements. The thermal insulation performance is excellent, with a thermal conductivity as low as 0.022 – 0.027W/(m・K), which is far better than glass magnesium, rock wool and other materials. It is one of the materials with the lowest thermal conductivity in the current building insulation field, especially in line with the insulation needs of low-temperature environments such as cold storage. Moisture resistance is also outstanding. The water absorption rate of the core material of the closed-cell structure is ≤1%. In high-humidity environments, such as cold storage and basements, it is not easy to absorb water and deform, and can maintain structural stability for a long time. In terms of mechanical strength, the board has a bending strength of ≥15MPa and a compressive strength of ≥0.25MPa, but it is light in texture, weighing about 8-12kg per square meter, and is suitable for large-span roof or wall structures, achieving a perfect balance between lightness and high strength.

Tell us your special requirements for sandwich panels

If our standard styles don’t quite meet your needs, we also offer custom made services.

General Faq

Design your beautiful Elementor FAQ widget and get more traffic to your website.

How to ensure quality?

Delivery time?

What is the payment method?

What are the benefits of buying products from ZHUOZHU?

What is the service life of sandwich panels?

ZHUOZHU BLOG

Learn about manufacturing processes, technologies and materials

Metal roofing that looks like shingles

Within the product range of stone-coated steel roofs, Shingle Tile stands out as a distinctive option—it is often referred to […]

Stone-Coated Steel Roofing: The Ideal Choice Combining Metal Strength and Traditional Aesthetics

Many homeowners, when looking to replace their roofs, desire both the durability of metal and the aesthetic appeal of traditional […]

Maintenance of Synthetic Resin Roof Tiles: A Practical Guide to Extending Service Life

Synthetic resin roof tiles, as commonly used roofing and wall covering materials in construction, have their durability closely linked to […]