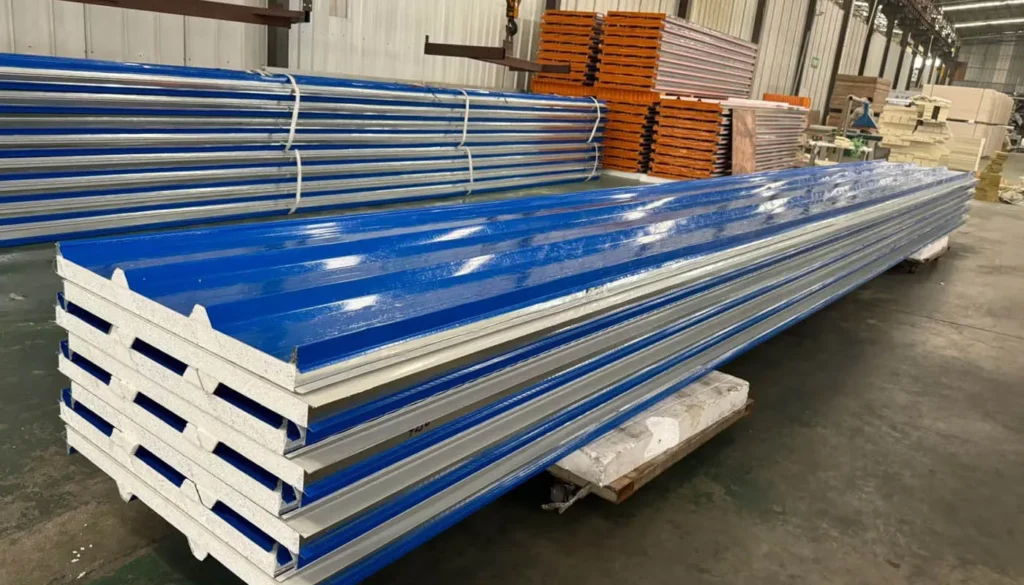

Introduction to Polyurethane Foam (PUF) Panels

Polyurethane Foam (PUF) panels represent an advanced insulation solution consisting of a rigid polyurethane core sandwiched between metal facings. These engineered panels offer exceptional thermal performance (typically 0.022-0.028 W/mK), structural integrity, and fire resistance, making them ideal for demanding construction and industrial applications.

Technical Specifications and Panel Types

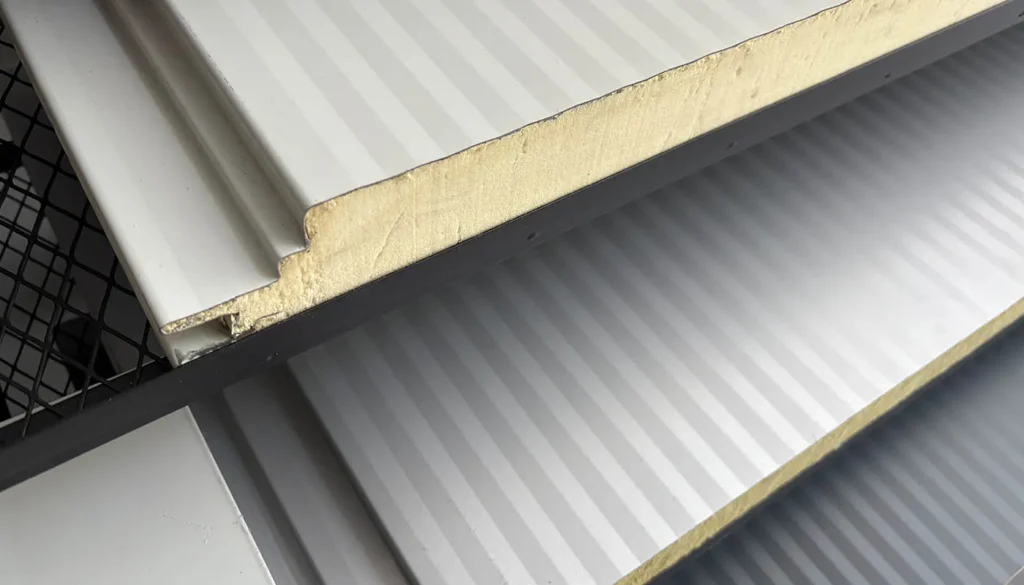

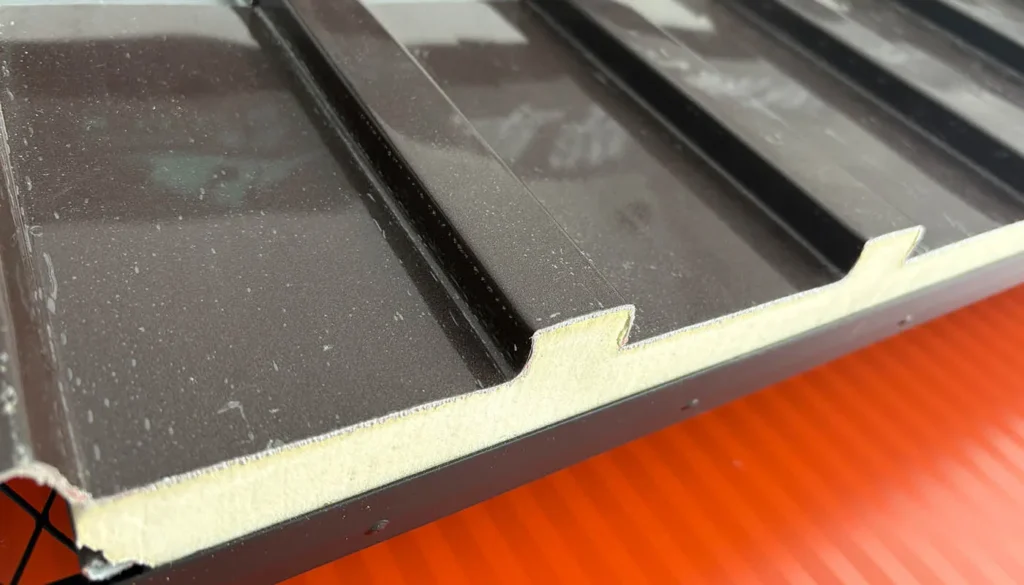

1. Structural Composition

- Core Material: High-density polyurethane foam (32-45 kg/m³)

- Facing Options:

- Galvanized steel (0.4-0.7mm)

- Aluminum (0.5-1.0mm)

- Stainless steel (for specialized applications)

- Standard Thicknesses: 30mm, 50mm, 75mm, 100mm

- Fire Ratings: Typically Class B1/B2 (EN 13501-1)

2. Performance Characteristics

| Parameter | Specification Range |

|---|---|

| Thermal Conductivity | 0.022-0.028 W/mK |

| Compressive Strength | 150-300 kPa |

| Operating Temperature | -50°C to +110°C |

| Water Absorption | <3% by volume |

Industrial Applications

1. Building Construction

- Wall Systems: Prefabricated structures using PUF wall panels demonstrate 30-40% improved energy efficiency compared to traditional materials

- Roofing Solutions: PUF roofing sheets provide U-values as low as 0.25 W/m²K when properly installed

2. Temperature-Controlled Environments

- Cold Rooms: Panels with 100-150mm thickness maintain consistent -25°C environments

- Clean Rooms: Antimicrobial PUF variants meet ISO Class 5-8 requirements

3. Specialized Installations

- Industrial Doors: 50mm-75mm thick panels for loading bays

- Modular Buildings: Complete prefabricated structures using sandwich panel systems

Manufacturer Selection Criteria

When evaluating PUF panel manufacturers, consider these critical factors:

- Certifications

- ISO 9001:2015 quality systems

- FM/UL fire performance certifications

- EN 14509 factory production control

- Technical Capabilities

- Custom panel fabrication (curved, tapered, or perforated)

- In-house testing facilities for thermal and structural performance

- BIM-compatible product data

- Supply Chain Considerations

- Minimum order quantities

- Lead times for standard vs. custom products

- Regional distribution networks

Installation Best Practices

- Structural Considerations

- Maximum span: 3.5m for wall panels, 2.5m for roofing

- Expansion joint requirements: Every 12m linear

- Sealing Requirements

- Butyl-based sealants for longitudinal joints

- Mechanical fasteners at 300-400mm spacing

- Maintenance Protocols

- Annual inspection of panel joints and fasteners

- Cleaning procedures for different facing materials

Market Trends and Innovations

Recent developments in PUF panel technology include:

- Nano-enhanced cores for improved fire resistance

- Integrated photovoltaic options for roofing panels

- Smart panels with embedded IoT sensors for condition monitoring

Conclusion

PUF panels offer a technically superior solution for modern construction challenges, combining excellent thermal performance with structural efficiency. When specifying these systems, careful attention to manufacturer capabilities, project requirements, and installation methodologies ensures optimal performance throughout the building lifecycle.

For projects requiring specialized solutions, consult with technical representatives from leading manufacturers to discuss:

- Custom panel configurations

- Performance validation testing

- Value engineering opportunities