Rock Mineral wool sandwich panels are high-performance building materials that integrate fire resistance, thermal insulation, sound absorption, and load-bearing capabilities. Their exceptional overall performance makes them an ideal cladding solution for modern industrial plants, logistics warehouses, commercial buildings, and clean rooms—places with stringent requirements for safety and energy efficiency.

Core Advantage: Superior Fire Safety

The most prominent advantage of rockwool sandwich panels is their unmatched fire performance. The core material, made primarily from natural basalt rock and other minerals, is melted at temperatures exceeding 1450°C and spun into inorganic fibers using advanced centrifugal technology before being solidified. This unique composition and manufacturing process result in exceptional fire resistance properties, effectively preventing the spread of flames and meeting or exceeding the most stringent building fire safety codes, providing crucial protection for life and property.

Perfect Balance of Performance

Beyond top-tier fire protection, rock wool sandwich insulation board excel in other areas:

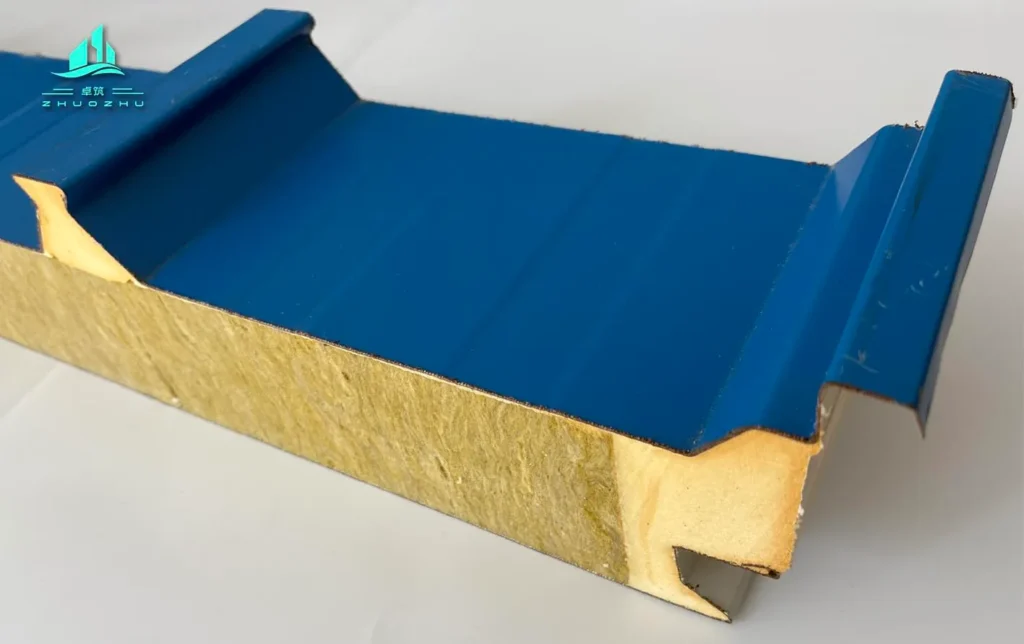

- High-Efficiency Thermal Insulation: The interwoven 3D fiber structure contains numerous air pockets, creating an excellent thermal barrier that minimizes heat loss in buildings, significantly reduces heating and cooling costs, and aligns with the energy-saving principles of green construction.

- Excellent Sound Absorption & Noise Reduction: The porous fibrous structure effectively absorbs and blocks sound wave transmission, creating a quiet and comfortable interior environment, which is particularly suitable for noise-sensitive applications.

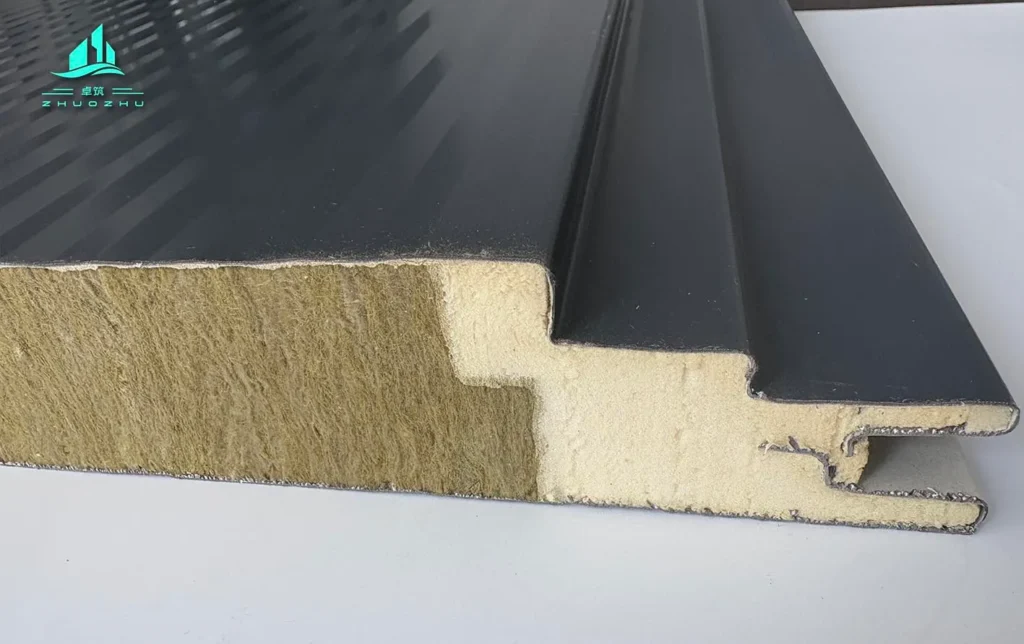

- Good Load-Bearing Capacity & Stiffness: The panels are composite structures, bonded with high-strength adhesives to sturdy metal facings (typically color-coated steel or stainless steel), offering high structural strength, resistance to bending and compression, and enabling their use in walls and roofs to directly bear loads.

Wide Range of Applications

Due to their versatility, rock mineral wool sandwich panels are widely used in:

- Industrial and Civil Construction: Wall and roof systems for factory workshops, warehouses, office buildings, and sports halls.

- Cleanroom Engineering: Production facilities in industries with extreme cleanliness requirements, such as pharmaceuticals, electronics, and food processing.

- Prefabricated Buildings & Temporary Facilities: For rapid construction that is also safe and reliable.

- Shipbuilding: For thermal insulation and fire partitions in ship cabins.

Conclusion

Rock wool sandwich panels are more than just a building material; they represent a complete building envelope solution. They successfully combine multiple values—fire safety, energy efficiency, structural stability, and installation convenience—into one system, providing a solid and reliable foundation for constructing safer, more efficient, and more sustainable modern buildings.