I. Structural and Functional Characteristics of Cold Room Sandwich Panels

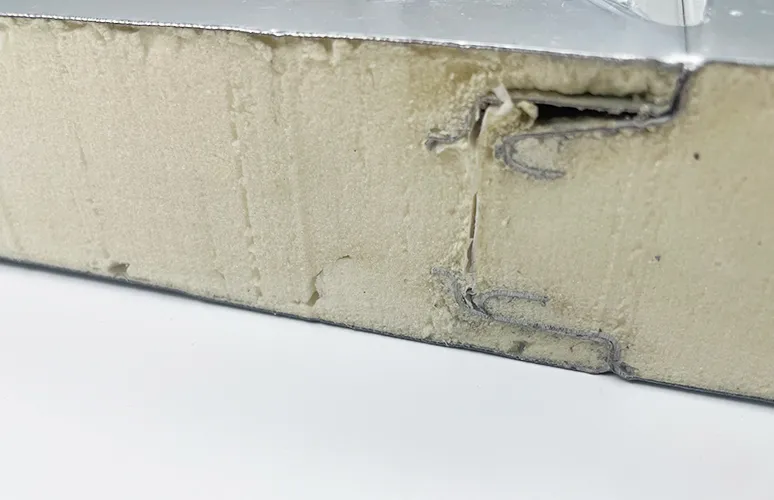

Cold storage sandwich panels are composite materials specifically designed for refrigeration environments, consisting of two metal face sheets and a central layer of insulating material. The metal face sheets typically use galvanized steel or stainless steel: the former offers excellent corrosion resistance suitable for high-humidity cold storage conditions, while the latter is preferred in hygienic-critical scenarios like food processing. Surfaces of the panels are often coated with polyester, PVC, or PVDF to enhance moisture and chemical corrosion resistance. The central insulating layer, usually made of polyurethane foam or polystyrene foam, forms an efficient thermal barrier through its closed-cell structure, blocking heat transfer to maintain stable indoor temperatures and reduce energy consumption of refrigeration systems.

Manufactured prefabricated in factories, these panels enable quick and convenient on-site installation. They are available in various sizes and thicknesses to adapt to different applications, and can be customized for specific design requirements. Widely used in commercial and industrial settings such as food processing plants, cold room warehouses, and distribution centers, they also serve residential needs like walk-in coolers and freezers, acting as fundamental building materials for modern cold chain logistics and preservation technology.

II. Key Factors Influencing Sandwich Panel Thickness Selection

- Precise Matching of Temperature Requirements

The target temperature of the cold storage facility is the core basis for thickness selection. For example, a freezer at -20°C requires a thicker panel (e.g., 150mm) compared to a 0°C fresh-keeping warehouse (e.g., 100mm) to resist external heat infiltration and prevent overloading of the refrigeration system. - Dynamic Adaptation to Climatic Conditions

External ambient temperatures directly affect insulation needs. In tropical regions, high temperatures accelerate heat conduction into the facility, necessitating thicker panels (e.g., over 120mm), while temperate regions can opt for 80–100mm to balance insulation and cost. - Facility Scale and Structural Requirements

Large cold storage warehouses, due to their vast space and strict uniformity requirements, need thicker panels (150–200mm) to ensure structural strength and minimize cold loss. Small commercial coolers, however, can use standard thicknesses of 60–100mm based on actual dimensions. - Industry Standards and Compliance

Local building codes and cold chain industry standards (e.g., ASHRAE in the U.S., GB/T series in China) specify clear requirements for thermal insulation performance. For instance, some regions mandate that the thermal transmittance coefficient (K-value) of cold storage panels must be ≤0.2W/(㎡·K), directly determining the minimum thickness. - Energy Efficiency and Sustainability Goals

Enterprises pursuing LEED certification or low-carbon operations often choose thicker panels (e.g., 200mm). Although initial costs increase, long-term energy savings (e.g., 15%–20% annual power reduction) justify the investment, aligning with green building trends. - Balancing Budget and Performance

Thickness correlates positively with cost: a 100mm polyurethane panel costs approximately 1.3 times more than an 80mm one. Enterprises should formulate plans based on operational cycles (e.g., economical thickness for short-term leased warehouses, performance priority for long-term self-use) to avoid excessive costs. - Special Requirements of Stored Products

Different products have varying sensitivities to temperature and humidity: fresh produce requires both insulation and breathability, suitable for 80–100mm thickness with moisture-proof coatings; pharmaceutical cold chains demand higher precision, often using 150mm+ thickness with additional vapor barriers to ensure temperature fluctuations ≤±2°C.

III. Value Extension of Sandwich Panels in Cold Chain Scenarios

From food supply chains to biomedical storage, the performance of cold room sandwich panels directly impacts product quality and operational costs. For example, a large fresh e-commerce warehouse using 120mm polyurethane panels with staggered jointing improved temperature stability by 30% and reduced annual energy costs by approximately CNY 120,000. In vaccine storage, panel thickness and airtightness are critical to bioproduct safety, often achieved through multi-layer composite structures for “zero cold bridge” design.

In the future, as cold chain logistics evolves toward intelligence and low carbon, sandwich panels will trend toward thinner profiles with higher insulation efficiency (e.g., vacuum insulated panel technology), while integrating sensor modules for real-time temperature monitoring and energy optimization, becoming an essential component of smart cold storage. Selecting the appropriate panel thickness is not just a technical decision but a systematic engineering task balancing efficiency, cost, and compliance—requiring tailored solutions to achieve optimal performance and investment returns.