The exceptional wind resistance of stone-coated steel roofing stems from its unique combination of metal’s inherent strength and the aesthetic appeal of traditional roofing tiles. Unlike conventional materials such as clay, concrete, or asphalt shingles—which are prone to cracking, lifting, or breaking under high winds—stone-coated steel panels are engineered to withstand extreme weather conditions without compromising durability or visual appeal.

For homeowners in wind-prone regions (e.g., coastal areas, hurricane belts, or open plains), stone-coated steel roofing offers unmatched reliability:

- Metal Core Strength: The high-tensile steel substrate resists bending and deformation, even under sustained wind loads exceeding 150 mph (240 km/h).

- Secure Fastening Systems: Advanced interlocking mechanisms and corrosion-resistant clips prevent uplift, a common failure point for traditional shingles.

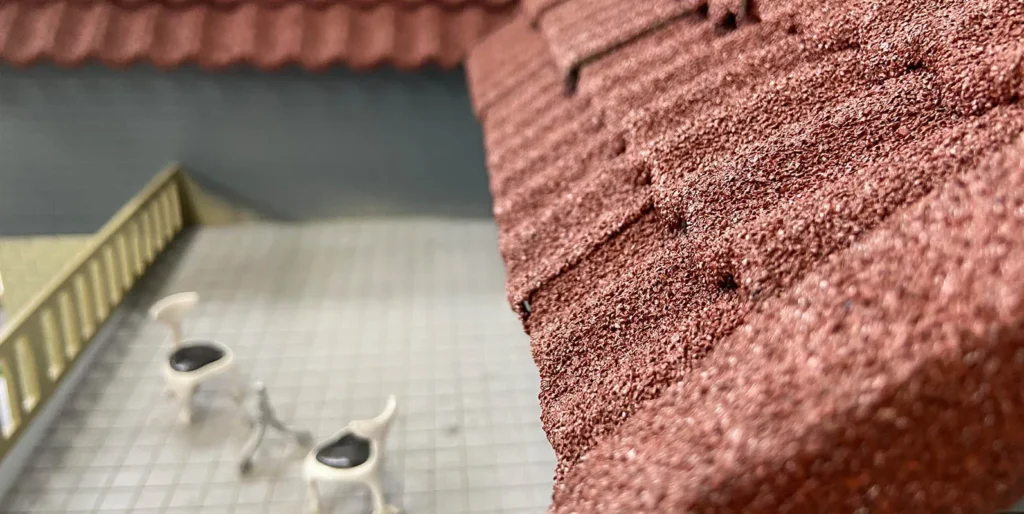

- Impact-Resistant Coating: The stone granule layer not only mimics the look of slate or terracotta but also adds an extra barrier against wind-driven debris.

Independent testing confirms that properly installed stone-coated steel roofs can endure Category 4-5 hurricanes, far outperforming organic or brittle alternatives. Whether facing relentless trade winds or violent storm fronts, homeowners can trust this system to remain intact and weathertight for decades.

Key Advantages Over Traditional Roofing:

✔ No loose or flying debris – Unlike tiles that can become projectiles in storms.

✔ Minimal maintenance – No need for post-storm repairs from wind damage.

✔ Long-term cost savings – Eliminates frequent replacements after severe weather events.

For ultimate peace of mind in high-wind zones, stone-coated steel roofing isn’t just an option—it’s the defensible choice.

1. Key Factors Affecting Wind Resistance

(1) Material Strength and Rigidity

- Steel Substrate: High-strength galvanized or galvalume steel (e.g., AZ150, AZ185, G550) with yield strength ≥550 MPa to resist wind-induced deformation.

- Stone-Coated Layer: Typically a fluorocarbon or polyester coating mimicking stone texture. Requires high adhesion (cross-cut test ≥Class 1) and impact resistance (≥50 kg·cm) to prevent peeling under wind loads.

(2) Fastening System Design

- Concealed Clips: Aluminum/stainless steel clips interlocking with panels, requiring pull-out resistance ≥2.5 kN each (per EN 10143).

- Exposed Fasteners: Paired with wind clips (spacing ≤400 mm) and structural sealant to prevent loosening from vibration.

- Perimeter Reinforcement: Edge zones need denser fasteners (20% reduced spacing) and reinforced flashing.

(3) Wind Load Calculation

- Per GB 50009 (China’s structural load code), evaluate:

- Basic wind pressure (e.g., 0.8–1.2 kN/m² for coastal areas).

- Gust factor (βz), shape coefficient (μs), and height coefficient (μz).

- Negative pressure (suction) is critical—verify panel bending resistance and fastener pull-out strength.

2. Wind Resistance Testing Standards

- Static Pressure Test (ASTM D6631):

- Positive pressure ≥4.5 kPa (equivalent to a Category 12 typhoon).

- Negative pressure ≥5.5 kPa (simulating uplift forces).

- Dynamic Fatigue Test: 100,000 cycles of pulsating wind loads to assess fastener durability.

- Reference: Japan’s JIS A 4702 requires stone-coated steel roofs to withstand 90 m/s winds without failure.

3. Wind Resistance Enhancement Measures

- Structural Design:

- Reduce purlin spacing (recommended ≤1.2 m) and add lateral bracing.

- Use trapezoidal ribs or stiffened panels (rib height ≥35 mm) to improve flexural rigidity.

- Construction Control:

- Fastener spacing ≤500 mm (≤300 mm in typhoon zones).

- Torque-controlled screws (e.g., 0.8–1.2 N·m).

- Seal joints with weatherproof sealant (movement capacity ≥25%).

- Maintenance: Annual post-storm inspections for fastener integrity and coating wear.

4. Wind Resistance Classifications

| Wind Pressure (kN/m²) | Wind Speed (m/s) | Recommended Roof Configuration |

|---|---|---|

| 0.5 (Inland) | 28.3 (10) | Standard fastening, 1.5 m purlins |

| 0.8 (Coastal) | 35.8 (12) | Dense fastening + wind clips |

| 1.2 (Typhoon Zone) | 44.0 (14) | Thicker panels (≥0.8 mm) + cross bracing |

5. Common Issues & Solutions

- Issue 1: Wind uplift causing panel detachment.

Solution: Upgrade to double-lock seam systems or add wind clips. - Issue 2: Coating erosion.

Solution: Use PVDF fluorocarbon coatings (20+ years weatherability) and periodic recoating.

Conclusion

Stone-coated steel roofing achieves wind resistance through high-strength materials, rigorous load calculations, and precision installation. In typhoon-prone regions, wind tunnel testing or CFD analysis is advised. Properly designed systems can withstand ≤Category 15 typhoons, but project-specific engineering is essential.