In modern architectural design, natural lighting and energy efficiency are key considerations. Translucent fiberglass roofing panels (FRP panels), with their excellent light transmission, lightweight strength, and weather resistance, have become an ideal choice for industrial plants, agricultural greenhouses, and commercial buildings. This article will explore their advantages and disadvantages and highlight their typical applications to help you determine if they suit your project needs.

1. Advantages of Translucent Fiberglass Roofing Panels

1. Superior Light Transmission

- Light transmittance ranges from 50% to 90%, providing uniform natural lighting and reducing daytime energy consumption.

- Available in diffused or frosted finishes to minimize glare, making them ideal for greenhouses and factories.

2. Lightweight Yet Durable, Easy to Install

- Weighs only half as much as glass but offers high impact resistance, reducing transportation and installation costs.

- Can be cut and drilled to fit various roofing structures, compatible with metal sheets and other roofing materials.

3. Excellent Weather and Corrosion Resistance

- Typically coated with UV protection, preventing degradation and extending lifespan to 10-20 years.

- Resistant to chemicals and moisture, suitable for harsh environments like chemical plants and coastal buildings.

4. Energy-Efficient and Eco-Friendly

- Reduces reliance on artificial lighting, lowering energy costs.

- Some models block infrared rays, minimizing heat buildup and improving energy efficiency.

2. Disadvantages of Translucent Fiberglass Roofing Panels

1. High Thermal Expansion Rate

- Expands and contracts with temperature changes, requiring expansion joints during installation to prevent leaks or warping.

2. Limited Heat Resistance

- Prolonged exposure to temperatures above 80°C (176°F) may cause resin degradation, making them unsuitable for high-heat environments like foundries.

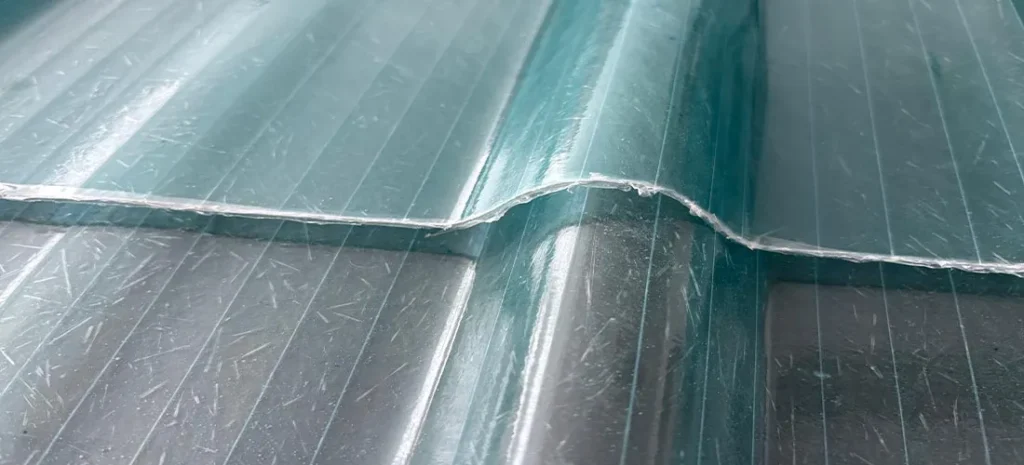

3. Surface Prone to Scratching

- Requires careful cleaning to avoid scratches that could affect light transmission and appearance.

4. Higher Cost Than Standard Plastic Panels

- More expensive than PVC but cheaper than polycarbonate (PC) panels, positioning them as a mid-to-high-end option.

3. Key Applications

1. Industrial and Warehouse Buildings

- Factories, warehouses, logistics centers: Replace metal roofing sections to provide natural lighting and cut energy costs.

- Workshop roofs: Ideal for automotive, food processing, and other industries requiring daylight.

2. Agricultural Greenhouses and Livestock Farms

- Greenhouses: Diffused-light panels prevent plant sunburn while retaining heat.

- Livestock barns: Durable and light-transmitting, suitable for animal housing.

3. Commercial and Public Facilities

- Malls, stadiums, exhibition halls: Used for skylights or facades to enhance aesthetics.

- Train stations, canopies, walkways: Lightweight and strong, ideal for long-span structures.

4. Specialized Construction Needs

- Chemical plants, coastal buildings: High corrosion resistance for harsh conditions.

- Energy-efficient buildings: Can be combined with solar panels for sustainable design.

4. Fiberglass Roofing Panels vs. Other Translucent Materials

| Feature | Fiberglass (FRP) | Polycarbonate (PC) | Glass |

|---|---|---|---|

| Light Transmission | 50%-90% | 80%-92% | 90%+ |

| Impact Resistance | High | Very High | Low |

| Temperature Range | -40°C~120°C | -40°C~135°C | Prone to cracking |

| Weight | Light | Lighter | Heavy |

| Cost | Moderate | Higher | Low |

Conclusion:

- Need affordability and good light transmission? → FRP panels are the best choice.

- Require extreme impact resistance? → PC panels are preferable.

- Looking for the lowest cost? → Glass, but consider safety and weight issues.

5. Buying Tips

- Choose UV-coated panels for longer durability.

- Opt for anti-fungal resin in humid environments to prevent yellowing.

- Increase thickness in snowy regions for better load-bearing capacity.

Final Thoughts

Thanks to their light transmission, lightweight strength, and weather resistance, translucent fiberglass roofing panels are a top choice for modern architectural lighting solutions. While they have limitations like thermal expansion and heat resistance, they remain widely used in industrial, agricultural, and commercial settings. For more details on specifications or custom solutions, consult a professional supplier!